What Standards Apply to Control Panels?

Kc service design, build, install, commission, and test

electrical

control panels meeting both customer and national build standards in a variety of industries. Panels include motor starters, motor efficiency panels using vsd’s and lv distribution. Where control is required, the panel can be incorporated with a plc or abb controller. We provide any combination of the following services:

site survey and consultancy

control system design, manufacture, installation and commissioning

design drawing using solidworks electrical

manufacture of control systems

full documentation and certification package

break down cover.

Multi-operational capability to suit a multitude of customer requirements. Works with all major engines including caterpillar, scania, volvo, deutz, etc. Customisable control panels to your exact requirements engine monitoring systems can be included into the control panel design. Logic controller operation available upon request. Manufactured under iso 9001 standards and certifications. Incorporating product design and electrical standards needed anywhere in the world.

With over 40 year’s expertise, we design and custom build electrical control panels/boxes within our state-of-the-art manufacturing facility in the heart of the west midlands. We offer the complete service from initial discussions with the client, through to design and specification of the control panel configuration, through to installation and maintenance (if required). Our services are tailored to our clients individual needs whether it’s a small, wall mounted cabinet, an individual control panel or a full bms/multiple unit, floor standing enclosure arrangement and, we have extensive experience in the manufacture of control systems ensuring we maintain the highest standards throughout the whole process- from initial design through to manufacture, testing and shipment.

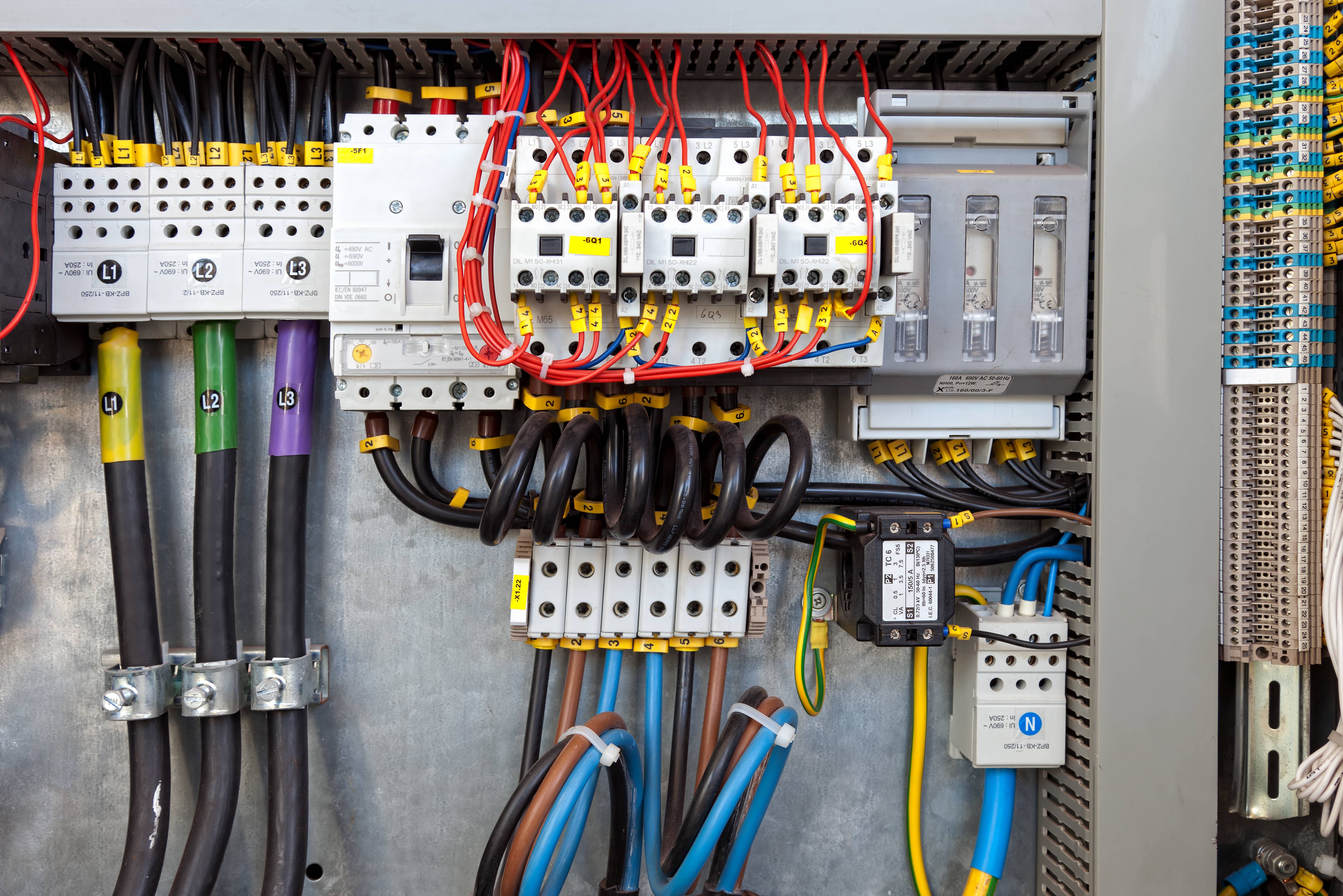

Power factor correction, surge protection and uninterruptable power supplies relays and contactors electricity is a common hazard within control panels, with electric shock, fires and arcing being of major concern. Control panels are designed to differing standards, based on age and country of manufacture, and whilst the panels might appear to be uniform on the outside, their content and layout internally can be quite different. In addition to electricity, pneumatic and hydraulic energy, as well as retained heat may also be a considerable risk to anyone who has need to enter. We advise learning through training courses to identify and deal with these risks safely.

Industrial Control Panel Maintenance

Controlsforce have the specialist skills and expertise to commission and optimise any of our electrical control systems. We offer all the advantages of big company support and back up, whilst remaining firmly focused on the virtues of close customer contact and genuine personal service. Control panel maintenance is a very important factor to ensure the smooth running of your plant or factory. Faulty equipment or regular down time can waste a company’s time and money.

If your equipment or plant is constantly having down time or looking a little tired, controlsforce can offer a review of your equipment or plant electrical control panels.

We are recognized as one of the outstanding electrical low tension panels suppliers in mumbai, maharashtra. The electrical lt panels are ideally designed to receiving power from source transformer or generator and distributing it through main feeders. Electrical lt control panels can be fabricated in both draw-out and non-draw out versions. Our design incorporates maximum system safety and reliability. Features • designed for high fault-levels up to 50ka. • provision of electrical and mechanical interlocking for security. • strong resistance to weather corrosion as well elegant finish through powder-coating and seven-tank treatment process of enclosures. • assembly of switchgear and bus bars ensures liberal spacing for cabling, access and maintenance.

All of our control panels come with a comprehensive documentation package upon hand over, this package briefly contains: as built drawings for control panel operation and maintenance manuals (on request) declaration of conformity (ce marking) complete and signed fat sheets parts list with recommended spares technical data sheets system integrator (2).

The manufacture and installation of a temporary control panel for 2 hazardous area gas extraction fans after the 30+ year old existing panel failed. For more information contact dave lawford on: 01484 905220 contact us water treatment our specialist teams carry out all types of instrumentation, control and power installations across the water treatment sector in the uk. These installations include modifications to existing equipment, improvements to site processes, new installations of equipment or maintenance of water treatment assets. We offer an experienced solution to electrical projects within the water treatment industry including design, installation and certification of all types electrical installations find out more.

The basics of electrical control panels

Electrical control panels come in a variety of different shapes and sizes, ranging from small wall-mounted boxes to row upon row of cabinets installed within a designated control room. In order to better understand how an electrical control panel box functions, we must explore their general design and typical components. Let’s begin by looking at their core structure, which comprises of an enclosure and a back panel.

Electrical control panels are designed and used to control mechanical equipment. Each one is designed for a specific equipment arrangement and includes devices that allow an operator to control specified equipment. Control panel consist of a controller. Controller may be plc, dcs, relay or some other type. It gives digital signal input signal to the mcc panel to start the motor. Control panel works based on the plc /dcs program or the relay logic. Instruments are normally connected to control panel. Indications for the interlocks also will be there in control panel. Nowadays single panel is used of using separate control and mcc panel.

Control panels for machinery electrical equipment, including control equipment for machinery, is required to comply with the electrical equipment (safety) regulations. If the electrical equipment complies with an appropriated standard, there is a presumption that it meets the principal safety objectives. The appropriate standard for control equipment for machinery is en 60204-1 in the eu or bs en 60204-1 in the uk. There are specific requirements for the manufacturer of electrical products, including affixing the ce mark for the eu or the ukca mark for the uk and the drawing up of a declaration of conformity. However, if an electrical control panel is specifically designed for the control of machinery it falls under the essential health & safety requirements (eshr’s) for machinery and is therefore compliance is included in the declaration of conformity for the machinery.

We can also undertake the design, construction and commissioning of electrical control systems and associated equipment, from starter panels to motor control centres. Many of our control panels feature microprocessor controllers and utilise variable speed drives to provide constant or proportional flow or pressure.

What is an electrical control panel?

Teepee also specialise in a range of wiring services including assembly of electrical control panels, wiring looms, cable harnesses, panel assemblies for a variety of sectors in the united kingdom. We specialise in providing quality services to the automotive , rail , renewable energy , agriculture and machinery sectors. If you’d like to find out more, click here to contact us. For further details on why teepee electrical are the ideal solution for all of your outsourcing needs, click here to view our company profile and find out more about our wide range of unrivalled services.

Need extra capacity for electrical services or control panel manufacture? want help upgrading obsolete components, on-site or remote fault diagnosis, or a complete control system. We'd be happy to take control. We have the extensive experience and in-house capabilities to deliver: one-off panel builds electrical cabinet assembly and wiring creation of wiring looms and harnesses.

Uk control panel services have been trading since 1996 and were incorporated in 2009, since that time we have been providing services for businesses nationwide and locally in staffordshire and the surrounding areas. We have built up an excellent wide and varied customer base with success in enabling customers to achieve their goal. Because of our customer satisfaction uk control panel services ltd has itself grown accordingly. As we are a member of the niceic and electrical contractors association (eca) you can be assured that all work carried out by us is to the highest standard.

Electrical control panels serve as an interface between the operator and the equipment they're operating. Pyrotek is recognized globally as a design-and-build leader of advanced control panels for electric heating systems, gas combustion systems, and other automated control systems. Over the years, pyrotek has specialized in making control panels for applications such as electric heating furnaces, heated launders, combustion furnaces, combustion preheaters, degassing furnaces, and pneumatic controls.

Electrical control panel components

What is an electrical control panel, exactly? think of an electrical control panel like the human body. Inside our bodies, we have many vital organs that control & monitor our surroundings. Similarly, an electrical control panel is a crca ms sheet enclosure that contains electrical switchgear that controls and monitors a mechanical process electrically. Power control center (pcc panel) let's get started! first, let's talk about the power control center (pcc panel), pcc panel contains all of the electrical switchgear like an air circuit breaker, mcc's, mcb, and suitable size aluminum or copper busbar. The main circuit breaker is where the power comes into the control panel for all of the switchgear.

Manes controls have manufactured electrical control panels for many industries in warrington, united kingdom and throughout the world. We are pleased to accept the whole spectrum of orders ranging from small single starter control panels through to form 4 fully tested mcc’s and systems of any size.

Here you’ll find some of the most common components of today’s modern electrical control panel. Communication interfaces one of the primary components that all electrical control panels will have is a type of controller that allows operators to interact with the panel, control its functions and send commands. Such commands are often transferred to the panel via components like a human machine interface (hmi) designed to provide operators with a visual interface of how different components in the panel are functioning. Motor control oversight most electrical control panels are designed to provide motor control solutions, which is why they’re often equipped with drives and contactors to monitor motor functions.

An employee was instructed to carry out work on an electrical control panel to reverse the phases and reverse the conveyor that had blocked. The panel was still live and electrical shorting resulted in arcing and caused burns to his face and arms. He had not received training in electrical work.

Comments

Post a Comment